Core Cutting and Forming Machines

1. Rectangular Core (Wound) Cutting and Forming Machines

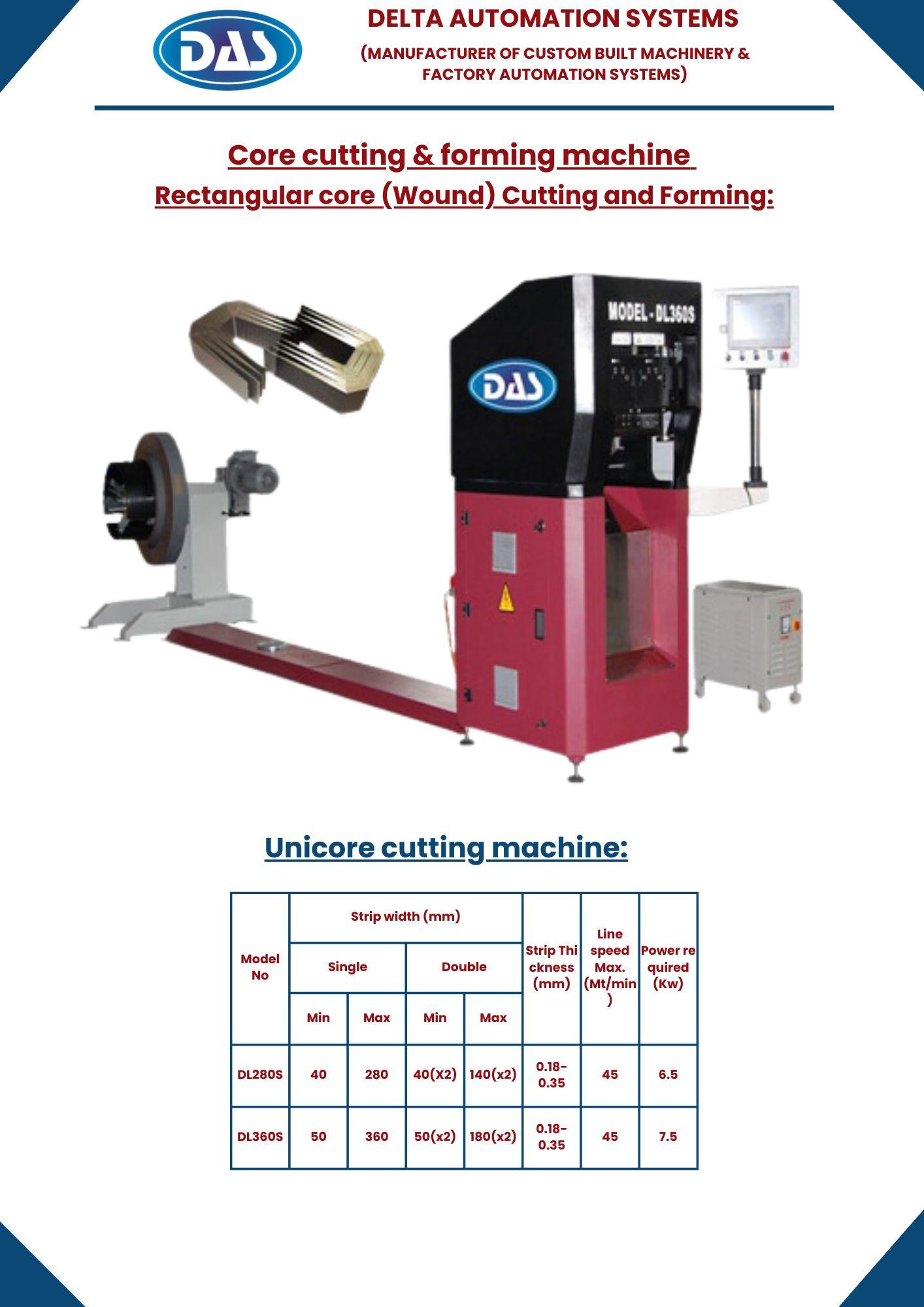

i. Unicore Cutting Machine (DL280S & DL360S)

- Purpose: Manufacture single or double transformer cores in predefined sizes and shapes.

- Key Features:

- PLC-controlled strip forming.

- Automatic core formation (inside-outside lamination).

- Operator inputs core size and design via HMI.

- Major components: Core cutting machine, de-coiler assembly, strip sensors.

Specifications:

| Model | Strip Width (mm) | Strip Thickness (mm) | Max Line Speed (m/min) | Power Required (kW) |

|---|---|---|---|---|

| DL280S | 40-280 (Single), 40-140 (Double) | 0.18-0.35 | 45 | 6.5 |

| DL360S | 50-360 (Single), 50-180 (Double) | 0.18-0.35 | 45 | 7.5 |

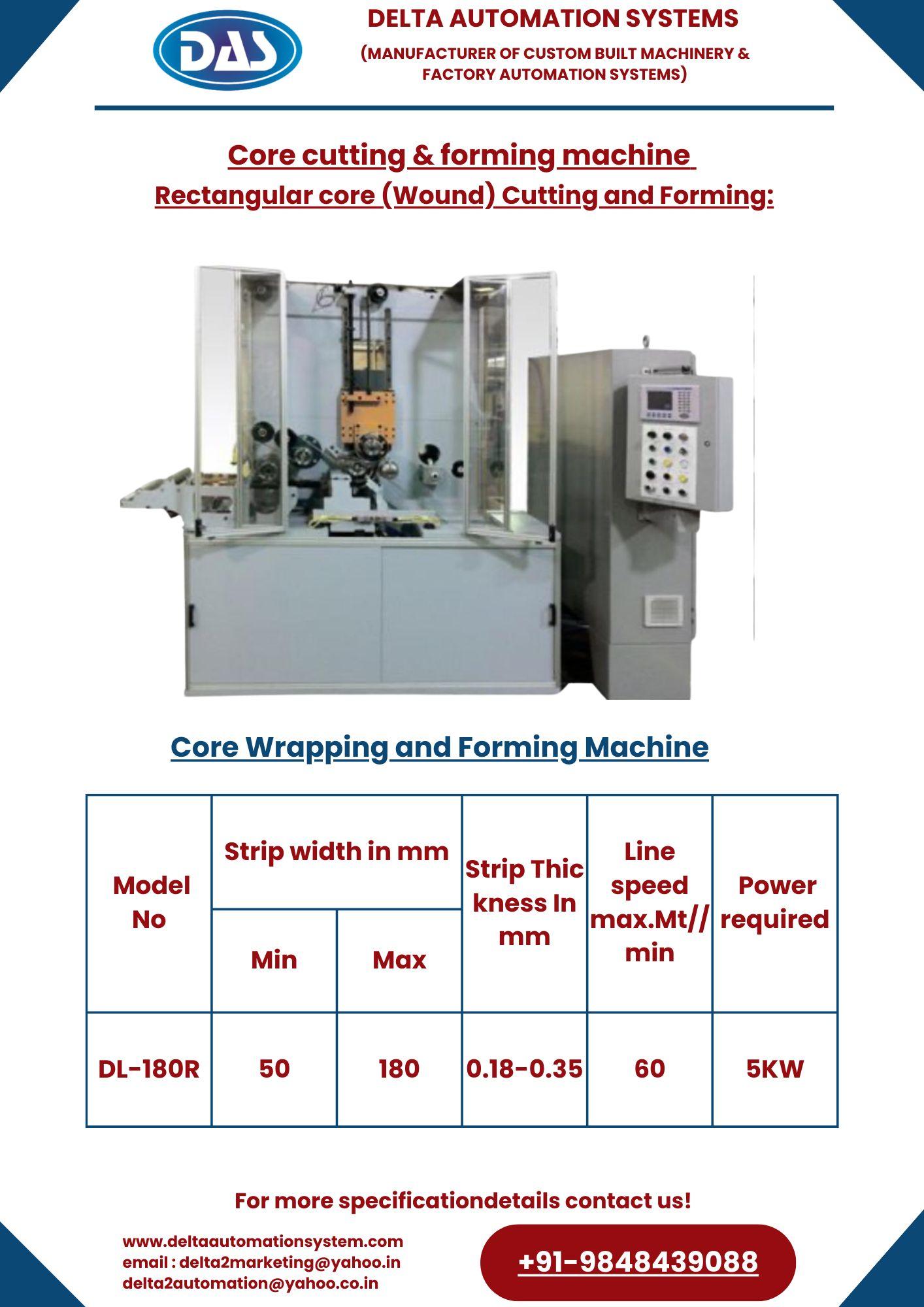

ii. Core Wrapping and Forming Machine (DL180R)

- Purpose: Forms wound cores into rectangular shapes for transformers (15-200 KVA).

- Key Features:

- High-speed hydraulic press for forming CRGO cores.

- External and internal hydraulic cylinders for dimension precision.

- Automated conveyors for core transfer during forming.

- Stress-relieved prefabricated machine body for long-term accuracy.

Specifications:

| Model | Strip Width (mm) | Strip Thickness (mm) | Max Line Speed (m/min) | Power Required (kW) |

|---|---|---|---|---|

| DL180R | 50-180 | 0.18-0.35 | 60 | 5 |

2. Step Lap Core Cutting Lines (CRGO/CRNGO)

Models: CTL220 & CTL450

- Purpose: Grain-oriented laminations for transformer cores using the step-lap method.

- Key Features:

- Dual un-coiler and PLC-controlled coordination.

- Predefined lamination shapes and manual stacking (auto optional).

Specifications:

| Model | Strip Width (mm) | Lamination Thickness (mm) | Max Line Speed (m/min) | Power Required (kW) |

|---|---|---|---|---|

| CTL220 | 35-220 | 0.18-0.35 | 0-150 | 12.5 |

| CTL450 | 75-450 | 0.18-0.35 | 0-100 | 20 |

3. Amorphous Core Cutting and Stacking Machine (DARC 2500L)

Purpose: High-precision cutting and stacking of amorphous transformer cores.

- Key Features:

- High cutting accuracy (+/-1mm).

- Electromechanical shearing and servo motor feed roller.

- Automated un-coiling with speed control via VFD.

Specifications:

| Parameter | Details |

|---|---|

| Ribbon Width | 140-250 mm |

| Cutting Length (Min/Max) | 300-2500 mm |

| Max Stacking Height | 220 mm |

| Feeding Speed | 120 m/min (max) |

| Shearing Speed | 200 strokes/min |

| Decoiler Specs | Spool ID: 360-430mm, OD: 1200mm, Weight: 1100kg |

| Power Supply | 25HP, 3-phase, 50Hz |

| Air Supply | 6 bar minimum |

| Floor Space | 12m x 3.2m x 2.2m |

| Weight | Approx. 6000 kg |

For more details or specific requirements, contact Delta Automation Systems!