Rectangular core (Wound) Cutting and Forming.

1.Rectangular core (Wound) Cutting and Forming

The cutting line is designed and built for the production of grain-oriented laminations suitable for the assembly of electric transformer cores.

The cutting line is made up of machines whose coordination is managed by control software.

The line automates the functions necessary for the processing of the laminations, namely:

• Unwinding from the coil

• Admeasurements of the shapes;

• Conveying and cutting of the sheet;

• Stacking of the finished products.

In the stacking function, various degrees of accuracy can be reached depending on the Selected model of the machine.

The basic configuration provides for the de-coiler and the cutting machine and a stacker, which are to be selected between different types.

The operator’s task is to replace the feeding coils, to initially insert the sheet into the cutting Machine, to select the type and size of the shapes, to move the processed product away from the cutting line and he is also responsible for routine maintenance.

Delta Automation Systems has produced the manufactured the following machines:

1. Rectangular core (Wound) Cutting and Forming:

i.Unicore cutting machine:

DL280S DL360S

The Rectangular core cutting and forming machine is a PLC controlled strip forming machine used to manufacture pre-defined size and shape either single or double transformer cores from thickness 0.18 to 0.35.

The formation of core starts from inside to outside of loop; each lamination is accurately produced so as it nests perfectly with one before. Initially the operator has to insert the sheet into the machine and select size, shape of core design on HMI. That has to be produced on machine.

The Rectangular core cutting and forming machine consists of the following major elements

• Core cutting and forming machine

• De-coiler assembly

• Strip sensors and cable trays

|

Model No |

Strip width (mm) |

Strip Thickness (mm) |

Line speed Max. (Mt/min) |

Power required (Kw) |

|||

|

Single |

Double |

||||||

|

Min |

Max |

Min |

Max |

||||

|

DL280S |

40 |

280 |

40(X2) |

140(x2) |

0.18-0.35 |

45 |

6.5 |

|

DL360S |

50 |

360 |

50(x2) |

180(x2) |

0.18-0.35 |

45 |

7.5 |

For more specification details contact us!

ii.Core Wrapping and Forming Machine

DL180R

Delta Automation Systems manufactures the special forming press to form the word core to rectangular shape by 4ways hydraulic pressing. This machine was inline operating machine for the wound core jobs generated on our core cutting machine.

This High-speed hydraulic operated core forming equipment is suitable for forming CRGO wound core to required rectangular shape. This equipment was best suitable for Ratings 15KVA to 200KVA Transformers. One number of high pressures operated Hydraulic cylinders was used to maintain internal dimension and four numbers of external pressing cylinders are used to press the core from four sides to maintain dimensions as per design requirement.

One number of hydraulic operated cylinder mounted at bottom was used to lower the wound core from conveyor height and to lift the pressed core from pressing zone to conveyor height.

Two numbers of one meter long sliding type conveyors are used to transfer the core from loading side to unloading side.

One number of top Pressing cylinder was used to press the external fabricated clamp up to the mid position of core to retain external dimensions till strapping was done.

Structure: The body of the machine was Pre-fabricated and machined with plates and duly stress relieved for retaining its dimensions for long duration.

In built oil collector (If any leakage occurs during maintenance) tray was designed to full width of machine

Core Forming machine specifications:

|

Description |

Dimension |

|

Working Height: |

1125mm. |

|

Side pressing Cylinders: (Outside) |

4nos. Dia:125xst:150mm-2nos. Dia:125xst:100mm-2nos. |

|

I.D Opening Cylinder: |

Dia:200xSt:200mm-1no. One set of wedge type pads will be provided with machine. |

|

Supply Voltage: |

415V, 3ph, 50Hz-AC |

For more specification details contact us!

Core Wrapping machine specifications

|

Model No |

Strip width in mm |

Strip Thickness In mm |

Line speed max. Mt//min |

Power required |

|

|

Min |

Max |

||||

|

DL-180R |

50 |

180 |

0.18-0.35 |

60 |

5KW |

For more specification details contact us!

Step lap Core (CRGO/CRNGO) Cutting lines.

Step lap Core (CRGO/CRNGO) Cutting lines.

CTL220 CTL450

The CRGO core cutting line is designed and built for the production of Grain -Oriented laminations suitable for the assembly of electric distribution transformer cores with step lap system. Cutting line is made out of different sub-assemblies whose co-ordination is managed by Programmable logic control.

The Core Cutting machine consists of the following major Elements:

• Dual Un-coiler.

• Generating the Pre-defined shapes.

• Conveying the cut sheets.

• Stacking of finished products -Manual (Auto stacking -Optional).

|

Model No |

Strip width (mm) |

Cut lamination Thickness (mm) |

Line speed Max. (Mt/min) |

Power required (Kw) |

|

|

Min |

Max |

||||

|

CTL220 |

35 |

220 |

0.18-0.35 |

0-150 |

12.5 |

|

CTL450 |

75 |

450 |

0.18-0.35 |

0-100 |

20 |

|

For more specification details contact us!

|

|||||

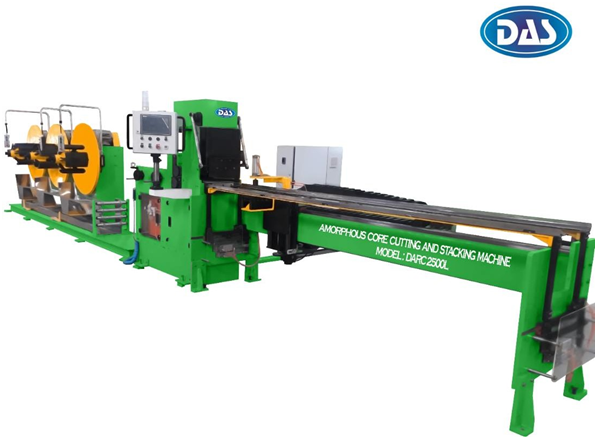

Amorphous Core Cutting and Stacking Machine.

Amorphous Core Cutting and Stacking Machine

DARC 2500L

|

SL.NO |

Specifications |

Size |

|

I |

Ribbon Cutting Sizes: |

|

|

|

Width of Ribbon: |

140 to 250mm. |

|

|

Min/Maximum cutting length of ribbon: |

300/2500mm |

|

|

Platform working length: |

2800mm |

|

|

Number of cuts/hours. |

360(Including feeding of max. length of sheet) |

|

|

Shearing Length: |

300-2500mm |

|

|

Max. Stacking height: |

220mm |

|

II |

Accuracy of Cutting and Stacking: |

|

|

|

Cutting Accuracy: |

+_1mm |

|

|

Position Accuracy: |

+_1mm |

|

III |

Productivity: |

|

|

|

Feeding Speed: Type: Feed Roller with servo motor. |

120mts/min max. |

|

|

Shearing Speed: By Electromechanical: |

200stokes/min |

|

|

Cycle time for 1000mm long ribbon cutting: |

4sec. |

|

IV |

Decoiler: |

|

|

|

Spool Inside Diameter: |

360-430mm |

|

|

Spool Outside diameter: |

1200mm |

|

|

Max. Carrying weight of Un-Coiler: |

1100kgs. |

|

|

Un-coiling speed: |

0-100rpm |

|

|

Speed Control |

By VFD |

|

|

Operating Mode: |

Manual or Auto; through line sensor signals. |

|

|

Spool Clamping: |

Manual. |

|

V |

PLC |

Mitsubishi/Omron. |

|

|

Touch Screen |

Mitsubishi/Omron. |

|

|

Pneumatics |

SMC/Festo. |

|

VI |

Requirements |

|

|

|

Power supply |

25HP/3ph; 50HZ |

|

|

Air supply |

6bar min |

|

VII |

Floor space |

12000Lx3200wx2200H |

|

VIII |

Weight of machine |

6000kg (Approximate) |