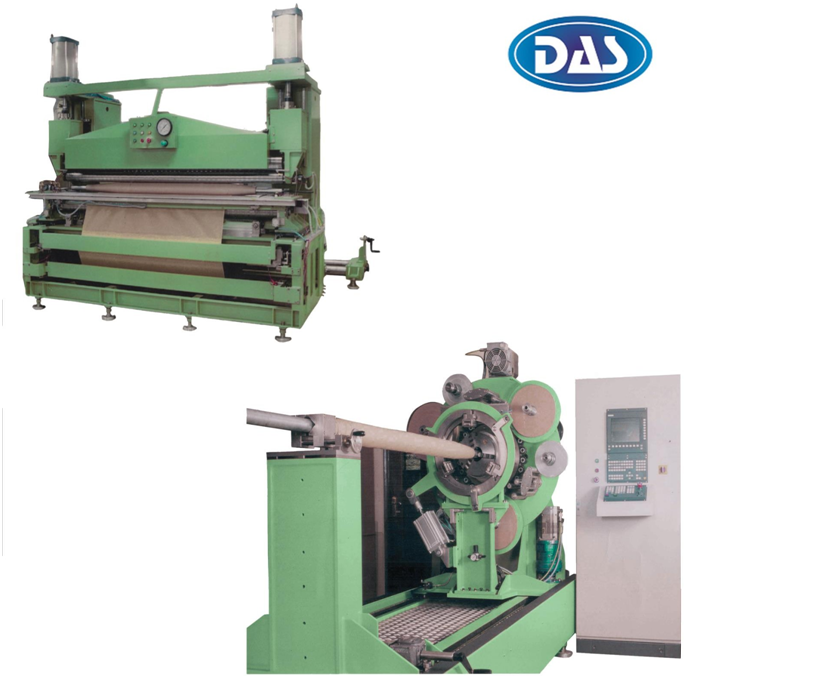

Full width paper Bushing wing machine.

Full Width Paper Winding Machine

Winding machines for condenser bushings are used to wind the insulation body for condenser bushings in oil impregnated paper O.I.P-Technology and resin impregnated paper R.I.P-Technology. The isolation body is made of creep paper, Kraft paper and aluminium foil.

Automatic winding machines for different bushing lengths can be built according to the customer's requirements. The maximum size of paper roll that can be loaded on above equipment is of diameter 400x3200mm long, firmly clamped between two manually adjustable conical supports moving on two number of guide shafts.

Both ends of conical supports are connected to the disc type brake system to adjust tension on paper. The position of paper roll can be adjusted with respect to machine by loosening one end of the conical support and tightening on the other end. The operator can adjust tension on either side of the paper roll from the operator position to avoid wrinkles on the paper during winding.

1.Paper cutting mechanism:

There are two numbers of cutters mounted on hardened and ground guide rods, the position of these cutters will be decided by the two servo-motors connected through ball-screw and nut mechanism. These two cutters will have individual manual adjustment for placing the cutters at required position. The raising and lowering of these cutters by a pneumatic cylinder through a two-position hand operated valve.

2.Paper preheating mechanism:

The paper will not get properly dried if it passes over a pre heating roller, because the amount of time that was in contact with preheating roller is very less, and also, we have to maintain the surface temperature of pre heating roller at higher side. So, we are proposing the preheating of paper by external light heating (micro oven type) when it passes through 3 to 4 idler rollers.

3.Bushing winding mechanism:

The Bushing will get supported by three numbers of rollers which are mounted at 120o inclination. All three supporting rollers will get drive to bushing which was coupled with variable speed worm geared motor by means of adjustable universal coupling.

All three rollers are heated to a temperature of 150deg. Centigrade through cartridge heaters mounted centrally inside the rollers. The temperature of the roller will be maintained constantly through non touching temperature transducer and PID control system. The bottom two supporting rollers move equally away when the diameter of the bushing increases during winding through a servo drive mechanism. The top roller is connected to pneumatic cylinders at its two ends and well guided by LM rail system.

For 3200mm long condenser bushing winding machine

|

Description |

Full width paper |

|

Paper roll dia (inner – Outer) |

75mm – 600mm |

|

Trimming Speed |

15m/min |

|

Supply type |

Electric & Pneumatic |

|

Diameter tolerance |

±0.10mm |

more specification details contact us!

Graded layer winding machine.

Graded Layer Winding Machine

Winding machines for condenser bushings are used to wind the insulation body for condenser bushings in oil impregnated paper O.I.P-Technology and resin impregnated paper R.I.P-Technology. The isolation body is made of creep paper, Kraft paper and aluminium foil.

Automatic winding machines for different bushing lengths can be built according to the customer's requirements. The maximum size of paper roll that can be loaded on above equipment is of diameter 400x3200mm long, firmly clamped between two manually adjustable conical supports moving on two number of guide shafts.

Both ends of conical supports are connected to the disc type brake system to adjust tension on paper. The position of paper roll can be adjusted with respect to machine by loosening one end of the conical support and tightening on the other end. The operator can adjust tension on either side of the paper roll from the operator position to avoid wrinkles on the paper during winding.

1.Paper cutting mechanism:

There are two numbers of cutters mounted on hardened and ground guide rods, the position of these cutters will be decided by the two servo-motors connected through ball-screw and nut mechanism. These two cutters will have individual manual adjustment for placing the cutters at required position. The raising and lowering of these cutters by a pneumatic cylinder through a two-position hand operated valve.

2.Paper preheating mechanism:

The paper will not get properly dried if it passes over a pre heating roller, because the amount of time that was in contact with preheating roller is very less, and also, we have to maintain the surface temperature of pre heating roller at higher side. So, we are proposing the preheating of paper by external light heating (micro oven type) when it passes through 3 to 4 idler rollers.

3.Bushing winding mechanism:

The Bushing will get supported by three numbers of rollers which are mounted at 120o inclination. All three supporting rollers will get drive to bushing which was coupled with variable speed worm geared motor by means of adjustable universal coupling.

All three rollers are heated to a temperature of 150deg. Centigrade through cartridge heaters mounted centrally inside the rollers. The temperature of the roller will be maintained constantly through non touching temperature transducer and PID control system. The bottom two supporting rollers move equally away when the diameter of the bushing increases during winding through a servo drive mechanism. The top roller is connected to pneumatic cylinders at its two ends and well guided by LM rail system.

For 3200mm long condenser bushing winding machine

|

Description |

Full width paper |

|

Paper roll dia (inner – Outer) |

75mm – 600mm |

|

Trimming Speed |

15m/min |

|

Supply type |

Electric & Pneumatic |

|

Diameter tolerance |

±0.10mm |

|

For more specification details contact us! |

|